Request A Callback

About Metal Fabrication

Our quality management system is based on the ISO 9001-2008 & 14001 standard, meaning every metal fabrication product is rigorously tested before leaving our factory floor. Every employee of Uma Poly has the skills necessary to build high-quality products for our customers.

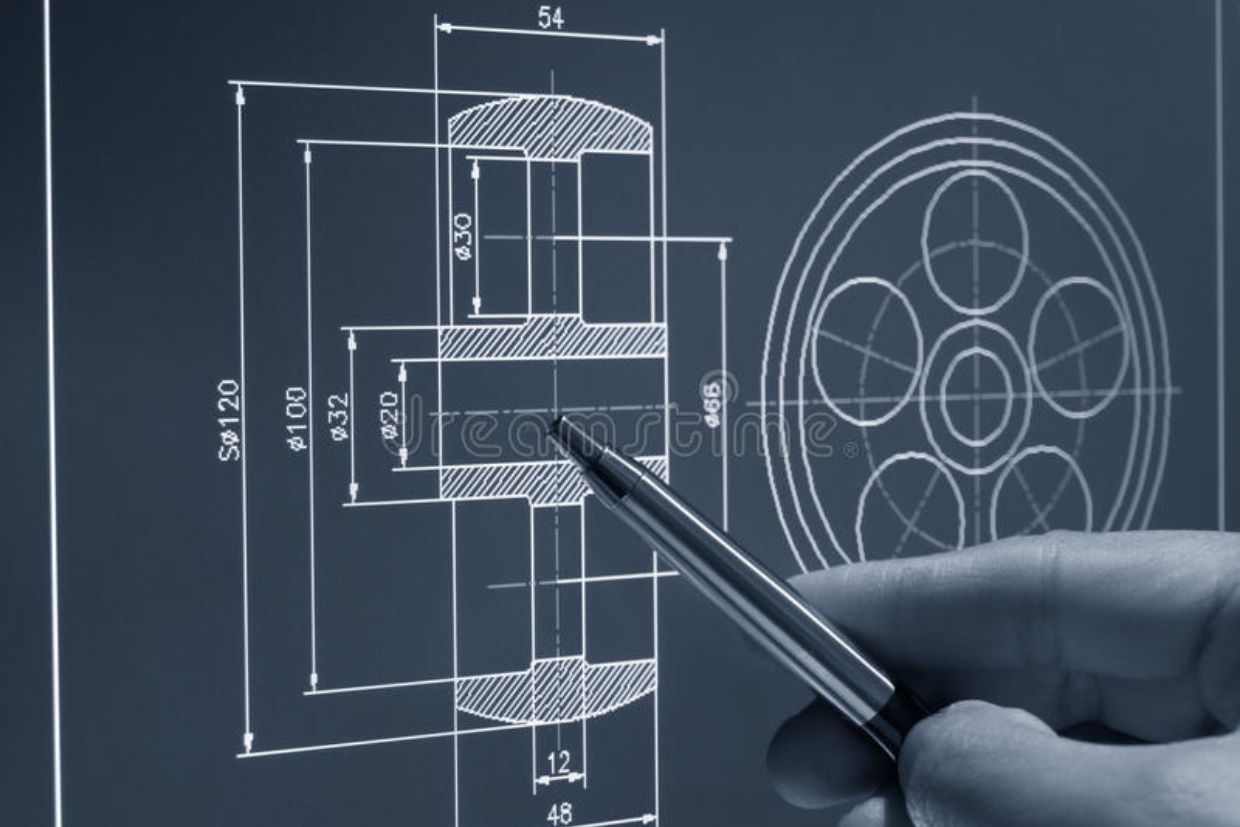

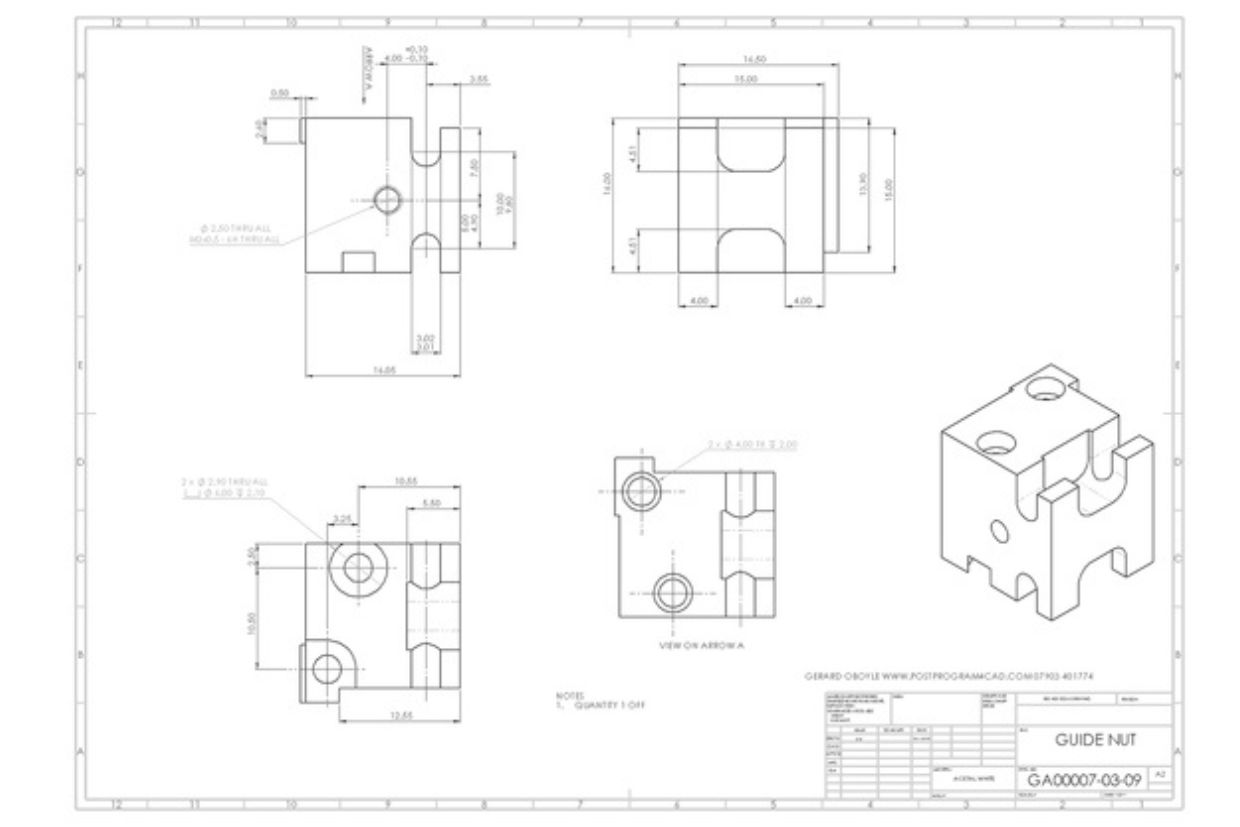

Designing

3D designing and 2D designing of the mechanical drawings could be done in the required format. CAD design reading and editing is easily done in-house. Further, the designers are able to get the designs done in-house for virtual representation before the actual laser cutting is done.

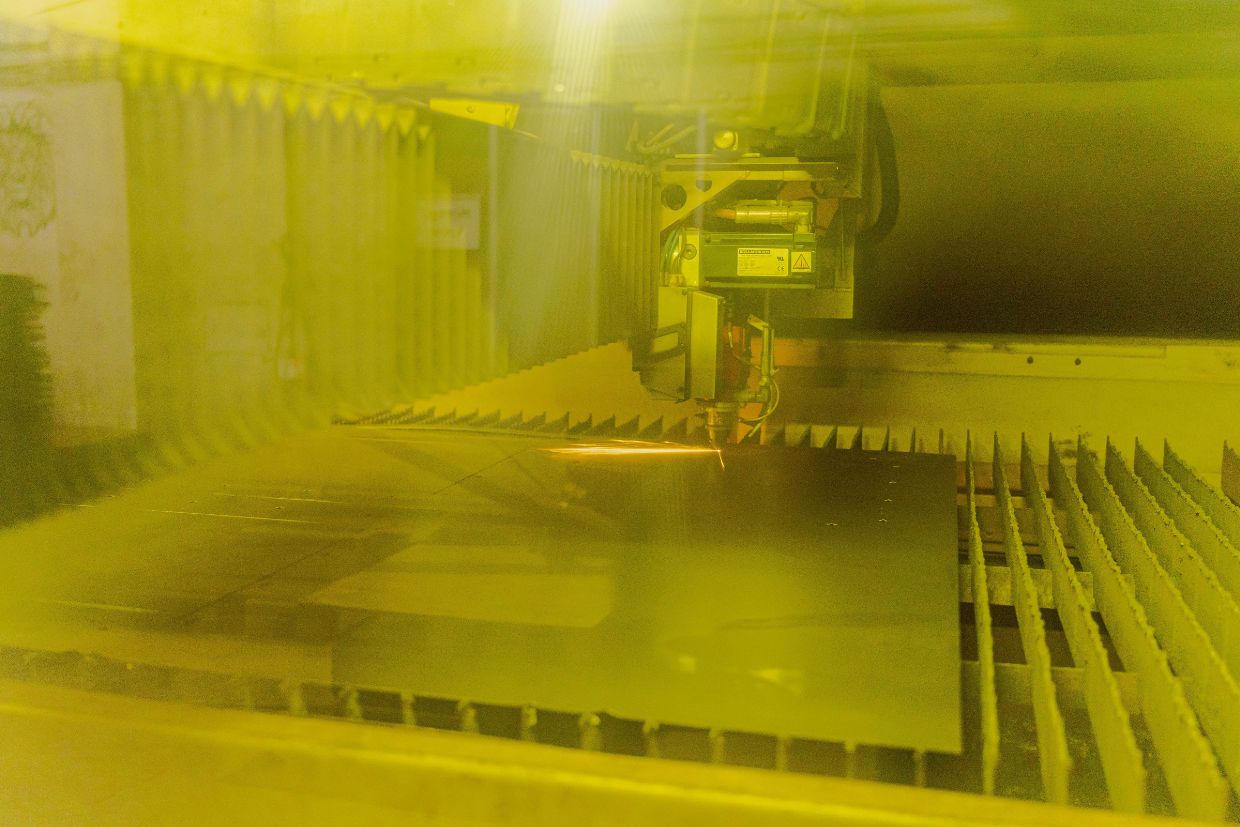

Laser Cutting

Italian Laser cutting Salvagnini is an end-to-end CNC laser cutting service which gives option to cut any kind of sheet metal with thickness up to 10mm. It’s a Class 1 machine in safety with single -optic head cooled without gas. Machine can be configured for modular automation for precise and unmanned operations.

Press Shop

As part of metal fabrication, Uma Poly has all required tools and equipment required for metal fabrication. Starting with bending, Uma Poly has CNC Hydraulics press brakes to delivery maximum productivity and delivery. Designed to adapt both European and Promecam style tooling. With bending of 2.5mm sheet metal (Mild steel) and 90◦ U bending easily done with tool changes as per need. Uma Poly also has multiple Mechanical Brake Pressfor fabrication related jobs.

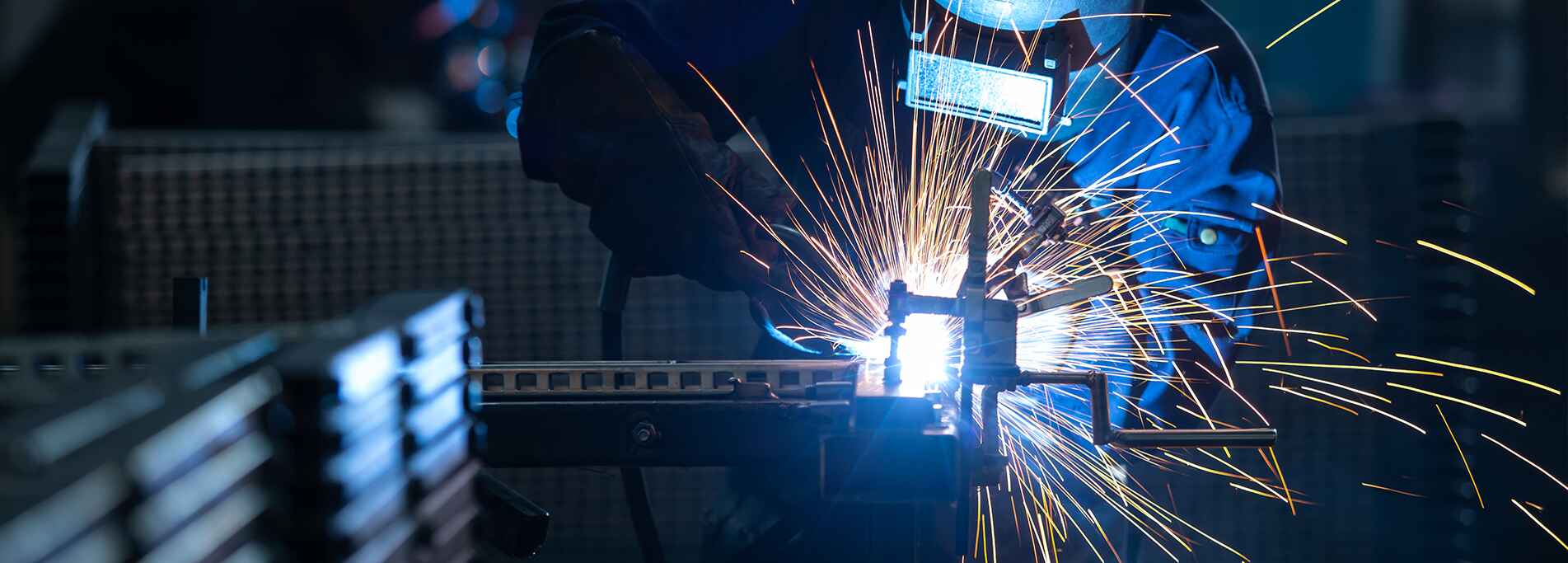

Welding

Mig Welding and Spot Welding are done In-house for multiple products. These tools are used for varied fabrication jobs and products where these create precision on the edges without being visible after Power Coating.

Pre-treatment of Metals

We have an in-house Pre-treatment set-up for all kind of metals, with multiple chemical tanks and water tanks to ensure a rust-free metal is available before Powder Coating. Set-up is designed for all kind of mild steel with automated loading and un-loading using crane.

Automated Paint shop

Multiple chemical and Water tank are build-up to cater up to 30k sqft. of paint per day with 3 shifts working. The automated paint shop is designed for handling products upto 6ft wide and 20mm thick. Two heat chambers ensure a flawless coating on different metals.

Our Memberships

Client Testimonial

Great looking name plate, Verified Purchase, Classy name plate for apartment door.

James Poonnolly

I purchased two name plates for my Bungalow. These were LED name plates, and these have survived the whims of weather. It’s a really good product.

S Chandgothia

Received the custom designed plaque, it has come out nice, the quality is worth the money.

Anjula Roy

Received the product awesome finish great service on customization.

Rollins Roy

I just received the Name Plaque and I am Super Happy with how the Name Plaque turned out. Thank you.

Mellisa Fernandes

I purchased two name plates for my Bungalow. These were LED name plates, and these have survived the whims of weather. It’s a really good product.

Rishi Agarwal

Exactly as expected in size and quality is even better than I imagined it would be. The Matt finish and smooth edges are perfect. Love it. But without hesitation